cnautotool offical blog

the blog of www.cnautotool.comcnautotool offical blog

the blog of www.cnautotool.comJohn Deere Service Advisor

John Deere Diagnostic tool Support Languages: English, French, German, Italian, Portuguese, Russian, Spanish.

John

Deere Service Advisor Agriculture workshop service manual, repair

manual, electrical wiring diagram, hydraulic diagram, diagnostic,

assembly and disassembly engine, transmission.

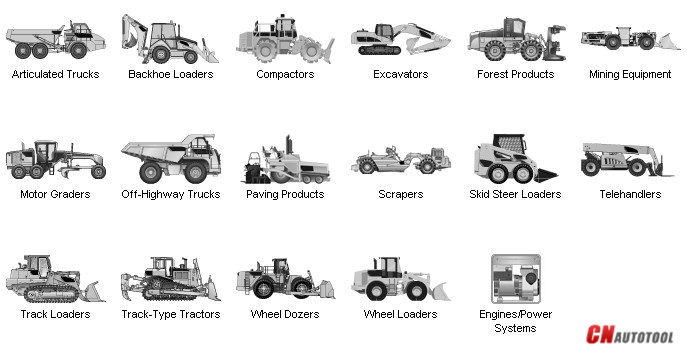

John Deere AG

Management Solutions, Attachments, Backhoes, Combines and Headers,

Cotton Harvestings, Excavators, ForkLifts, Hay and Forages, MAte Hand

Cut and Shredderses, Plantings and Seedings, Skid Steers, Sprayers,

Sugar Cane Harvesters, Tillages, Tractors, Worksite Pro Attachments.

John Deere Service Advisor CF (Construction and Forestry), workshop

service manual, repair manual, diagnostic, electrical wiring diagram,

hydraulic diagram John Deere.

John Deere Service Advisor CCE (Commercial and Consumer Equipment)dealer technical assistance, diagnostics, connection readings, calibrations, interactive tests, specification, tools, assemble and disassemble presented all models John Deere Construction Equipment and some models Hitachi, Euclid, Bell and Timberjack.

V5.2 Software

Supports John Deere vehicles up to 2018

Size: 250 GB

Region: All regions

Type: Service and Repair Information

Version: V5.2

Service Advisor for John Deere contains:

Tractors

Tractor Attachments

Transmission

Combines and Headers

Cotton Harvesting

Cutting and Mowing

Harvester

Harvester Head

Hay and Forage

Landscaping

Mate. Hand Cut. and Shredders

Planetary Drive

Planting and Seeding

Scraper

Skid Steer

Loader

Compact Loader

4WD Loader

Snow Products

Sprayers

Sugar Cane Harvesters

Sugar Cane Planter

Tillage

Vertical Tillage

Utility Vehicles

Field and Crop Solutions

Golf and Turf Products

GPS Receiver

Guidance

Hydraulic Power Pack

Information Management

LG Attachments

Motor Inverter

OEM Engines

Commercial

Display

Excavator

Worksite Pro Attachment

Axles

AG

Apollo Series

Engine

Readings

Riding Lawn Equipment

Other

Boom

PTO

Telematics

John Deere 4WD Loader

John Deere Backhoe

John Deere Bundler

John Deere Compactor

John Deere Crawler

John Deere Delimber

John Deere Excavator

John Deere Feller Buncher

John Deere Felling Head

John Deere Forklift

John Deere Forwarder

John Deere Harvester

John Deere Harvester Heads

John Deere Landscape Loader

John Deere Log Loader

John Deere Logger

John Deere Mate. Hand Cut. and Shredders

John Deere Motor Grader

John Deere OEM Engines

John Deere Scraper

John Deere Skid Steer

John Deere Skidder

John Deere Slasher

John Deere Tractor

John Deere Tractors

John Deere Tree Harvester

John Deere Truck

John Deere Utility Vehicles

John Deere Winch

John Deere Worksite Pro Attachment

Model list:

John Deere 5720

John Deere 5820

John Deere 5620

John Deere 244J

John Deere 304J

John Deere JD904

John Deere JD1054

John Deere JD1204

John Deere JD1354

John Deere 70

John Deere 570

John Deere 40

John Deere 315

John Deere 240

John Deere 250

John Deere 260

John Deere 270

John Deere 3375

John Deere 4475

John Deere 5575

John Deere 6675

John Deere 7775

John Deere 8875

John Deere 60

John Deere 375

John Deere 328

John Deere 280

John Deere 70A

John Deere 44

John Deere 320

John Deere 575

John Deere 240 Series II

John Deere 250 Series II

John Deere 260 Series II

John Deere 270 Series II

John Deere 280 Series II

John Deere 332

John Deere 325

John Deere 51

John Deere 52

John Deere 67

John Deere 675

John Deere 675B

John Deere 313

John Deere 24A

John Deere 125

John Deere 317

John Deere CT322

John Deere CT332

John Deere CT315

John Deere 850

John Deere 260

John Deere 375

John Deere 385

John Deere 960

John Deere 900

John Deere 447

John Deere 7

John Deere 8

John Deere 8A

John Deere 10

John Deere 10A

John Deere 46

John Deere 485

John Deere 448

John Deere BH8

John Deere BH9

John Deere BH11

John Deere 911

John Deere BH7

John Deere 1905

John Deere 1200

John Deere 300

John Deere 305

John Deere 300CX

John Deere 300X

John Deere 553

John Deere HX10

John Deere HX14

John Deere MX10

John Deere MX8

John Deere MX5

John Deere MX6

John Deere MX7

John Deere HX20

John Deere CX20

John Deere RC60L

John Deere RC72L

John Deere RC72

John Deere RC78

John Deere 1800

John Deere E-GATOR

John Deere DB84

John Deere DB96

John Deere 50ZTS

John Deere 27ZTS

John Deere 35ZTS

John Deere 17ZTS

John Deere 27CZTS

John Deere 35CZTS

John Deere 50CZTS

John Deere 27D

John Deere 17D

John Deere 60D

John Deere 35D

John Deere 50D

John Deere CH8

John Deere 540

John Deere 2000

John Deere MCS

John Deere 2 Bag Bagger

John Deere 5080R

John Deere 5090R

John Deere 5100R

John Deere 5100RN

John Deere 5080RN

John Deere 5090RN

John Deere 5070M

John Deere 5080M

John Deere 5090M

John Deere 5100M

John Deere 790

John Deere 670

John Deere 770

John Deere 4300

John Deere 4700

John Deere 4400

John Deere 1050

John Deere 4200

John Deere 4720

John Deere 2320

John Deere 4600

John Deere 970

John Deere 2520

John Deere 4010

John Deere 4320

John Deere 4520

John Deere 4710

John Deere 4500

John Deere 4100

John Deere 4110

John Deere 4115

John Deere 4210

John Deere 4310

John Deere 4410

John Deere 4510

John Deere 4610

John Deere 870

John Deere 1070

John Deere 990HC

John Deere 2210

John Deere 3120

John Deere 4120

John Deere 3320

John Deere 3520

John Deere 3720

John Deere 2305

John Deere 3203

John Deere 4105

John Deere 3005

John Deere 4005

John Deere 2720

John Deere 3032E

John Deere 3036E

JOHN DEERE diagnostic adapter for construction equipment, agriculture, engines John Deere.

What can I do with one CAT Caterpillar ET Diagnostic Tool

Retrieve engine totally for fuel used, miles traveled, and hours operated.Display status of all parameters, such as engine speed, throttle position, timing advance, fuel flow, etc.View active and logged diagnostic codes to identify faulty sensors.

What can I do with one CAT Caterpillar ET Diagnostic Tool: CAT Communication Adapter III has to work with a computer, and we users can display the status of a group of parameters (temperatures, pressures, etc.) details: 1.Display Logged Event Codes to show engine over speeds, High temperatures, fuel consumption, etc;

2.View ECM’s current configuration and change user settings;

3.Perform diagnostic tests and calibrations, and calibrate;

4.Electro-mechanical and electro-hydraulic components;

5.Context sensitive help leads operator through every task diagnostic tools Cat ET can perform

6.Data Logger and Data Log Viewer allows recording of ECM signals for delayed troubleshooting capability.

Caterpillar ET is available with the language I want:

The most important reason why I choose Auto key Programmer CAT

Caterpillar ET Diagnostic Adapter III is that it is available with the

language what I want, the language it supports includes: Danish,

English, French, German, Italian, Japanese, Portuguese and Spanish

Support car list of CAT Caterpillar ET Diagnostic Tool :

With the CAT Diagnostic Tool, you can:

View active and logged diagnostics

View events where irregularities occurred and were logged by the ECM

View the status of a group of parameters (temperatures, pressures, etc.) simultaneously

Record and log performance data

Graph a group of status parameters

View the current configuration of an ECM

Change ECM configurations

Perform diagnostic tests

Perform calibrations

Print reports and diagnostic results

For some machine and engine products, additional functionality has been included with the service tool program

Features

Display, graph and log status parameters.

Retrieve prognostic data including histograms, engine totals for fuel used and miles traveled.

View active diagnostics and clear logged diagnostics. View events where

irregularities have occurred and have been logged by the ECM.

Perform calibrations to enhance performance of the ECM.

Customize the ECM with application-specific settings.

Over 100 custom Diagnostic, Information and Service features including:

– 2D and 3D Histogram plotting capability (engine software

support required).

– Custom Status screen groups

– Snapshots (Download and display snapshot data recorded by the

ECM)

– Configuration Aid that allows upload/download of same

configuration to multiple control modules

Customised Service Tool Options

Customized service tool name

Customized graphics for the splash screen and icons

Customized installation

Aftermarket differentiation, i.e., the tool for one customer does not work on the product of another customer.

Licensing options for customer management

Flash programming of the ECM(s)

Training demonstration allows familiarity with the tool’s primary functions without connecting to ECM(s)

Perform customized diagnostic tests to identify harness problems,

cylinder or component failures (Automatic Cylinder Cutout with cylinder

to cylinder fueling comparison)

More Details please contact us:https://www.cnautotool.com/goods-2485-2017A+Version+CAT+Caterpillar+ET+Diagnostic+Adapter+III.html

Mercedes Vediamo Xentry Das Developer Mode User Manual

MB Star Diagnosis Xentry/das

developer mode with Mercedes Vediamo for SCN coding no need SCN

account. Few Customer inquiry Star Diagnosis Xentry/DAS developer mode

Mercedes Vediamo, How to use the Mercedes Vediamo software?

CnAutotool.com share the Mercedes Vediamo Star diagnosis developer mode user manual as following.

MB Star Diagnosis Xentry Das with Vediamo Xentry/DAS Developer Mode

XENTRY MERCEDES DIAGNOSTIC SOFTWARE 2017 2 MB Star Diagnosis Xentry/DAS Developer Vediamo Mode User Manual

Here is MB Star Diagnosis Xentry/DAS Developer Mode User Manual, incl three part:

What you need for Mercedes Vediamo Xentry/DAS Developer Mode ?

When & why you should use Mercedes Vediamo Xentry Developer Mode?

How to use Mercedes Vediamo Developer Mode step by step?

THE MOST IMPORTANT NOTE: you are trying on your own risk!!!!!!!!

Be very careful when using the Developer functions! Many of them can

cause irreversible damage to the components of the vehicle and may cause

personal injury! Please be aware that modification to some specific

systems (airbags, braking systems) may make the vehicle unsafe for on

road use and may violate the local highway laws, rendering the car not

roadworthy in the legal aspect.

This is especially true for the SRS modules, where unintentional usage

of developer options may cause deployment of airbags/tensioners and

other aggressive restraint systems.

IMPORTANT NOTE: what do you need for Xentry/DAS Developer Mode?

– original Mercedes diagnostic tools like Super mb star c3 or HQ clone like SDconnect C4 china clone mux

– DAS/XENTRY with good installation

– a laptop running with Windows XP better

IMPORTANT NOTE: why & when should you use Xentry/DAS Developer Mode?

As a presumed DAS user you have probably learned already that there are

number of functions that would logically belong to the software options,

but they

are missing from the regular DAS installations. These include recoding

(variant coding) the control units without SCNs (Software Calibration

Numbers), de/activation of commercially sensitive options (in-motion

video of tv/dvd), recoding the configuration of airbag units, seat belt

reminders, changing the configuration of instrument clusters, restoring

damaged EEPROM contents for Comand/APS and other ECUs and many more.

There is also an additional benefit: sometimes control units record a

DTCs (error codes) that are filtered out by the production software.

Developer kit allows unfiltered view on the module’s error memory,

therefore allowing to see all stored trouble codes, including the masked

ones.

The reasons for disabling these functions in the DAS setups seen at the

dealership are very simple: firstly, risk associated with using them is

too high to open these tools to (very often) under trained and rushing

technicians; secondly, there are several legal obligations that put

restrictions on what the dealer can do and what he can not – for

instance, recoding tv-in-motion, airbags and emission-re lated systems

fall into this category. Thirdly, electronically damaged components very

often result in replacement, therefore repairing (recoding) would have

adverse effect on spare parts revenue.

Here is how to : clean ASSYST Plus Memory

Firstly, you need the mentioned Developer key made according to your LAN

ID. Before scrapping your old key, take note of the LAN ID (there are

some cases when it changes ie. when reconfiguring the hardware) and the

current License Key in the DAS. Both information can be found in the

licensing menu of Star Utilities. Then replace your current key with

Developer key, save and restart DAS. After selection of vehicle class

there should be now a new screen (in German, except V-Series and W221

where it comes in English) informing you about dangers associated with

using Developer Kit. You are good to go now.

In Mercedes Vediamo Developer mode : (tested version 11-2010)

Steuergerate (Control units) ->F3

Aufbau (Body) ->F3

ZGW (CGW) ->F3

Entwicklungen (Development data) ->F3

Steuergerate – Anpassungen (Control unit adaption) ->F3

Programmieren (Update) von Steuergeraten (Control module programming) ->F3

Steuergerat programmieren (Auswahl) (Program control unit (Selection)) ->F3

Now we have 2 options to flash the ZGW/CGW with, choose the correct one

Don’t panic ! if you choose the wrong file , it terminates process and you can do it over again

Confirm Flash pop-up with Ja (Yes)

After that it says : “Das Steuergerate wurde erfolgreich programmiert”

->”OK” it ask for a reset -> JA (Yes) ->

ECU Reset (FN_ECU_Reset) ->F3 again ->F3

Now you Complete full History wipe

Enable Comand DVD/TV in Motion (W211 W219) and OTHERS

USE THIS TIP WITH CARE AND COMMON SENSE !!! AND OBEY LOCAL LAWS.

In obd2tool.com Vediamo Developer mode :

Audio, Video, Navigation und Telematik ->F3

a screen might pop up with all kind of settings, ignore and press F2

New screen with ESD warning ->F3 COMAND /AUDIO -AUDIO 50 oder COMAND ->F3

Entwicklungsdaten ->F3

Steuergerate-Anpassungen ->F3 Steuergerate-Anpassungen (Variantencoderierung) ->F3

HU Parameter ->F3 scroll down to line: Driving speed is more than 0 kph and

Driving speed is more than 10 kph and BOTH enable them and ->F3 to confirm coding

Now you be able to watch DVD/TV when car is in motion

Uprate the speed limited in a gasoline (ME-series controller) engine control unit

Log on to DAS, connect to the car, select:

Control Units -> Drive -> ME-SFI 28 -> Development Data.

Then select the Control Unit Adaptations -> Explizite Kodierung

This option works quite the same in Diesel engine models, however i

found it more difficult to use (quite frequently modules are replying

with an error message to the attempt of recoding). I was able to

successfully remove the speed limiter on a CDI2 series module from the

W210 model and some others as well.

Addrear airbags to the AB control module

Control Units -> Body -> Airbag (AB) -> Development Data ->

Control Module Adaptations -> Variant Coding -> Fahrzeugausstatung

Kodieren

(the last menu entry can be slightly d ifferent in various module variants)

Select the drop-down list in the field Airbag Hinten Rechts and Airbag

Hinten Links – set to YES. Back up to the main Airbag menu, reset the

fault codes, cycle ignition, reset fault codes again and cycle the

ignition for 2nd time (this step is very important).

Addfog lamps to function as a cornering aid

Select Body, then Driver Side SAM -> Development Data -> Control

Unit Adaptations -> Variant Coding -> Abbiegelicht set to ON

(“ja”).

Then go to the Passenger SAM (if present, for example in 211/219 model

series) and similarly, perform the same coding in the second SAM unit. I

have found that quite often cars manufactured prior to year 2003 have

the relevant cornering lights option available in the left sam, however

right sam is missing it. Not a big problem since these are readily and

cheaply available from the second-hand market.

For all the onboard systems to recognize the new function you will also

need to recode the CGW or EZS and mark the appropriate factory option in

the adaptations.

Hidden error codes

For W211/W219/W230 series with SBC system, go to the Chassis->

Sensotronic Brake Control (SBC) then enter Development Data then call up

Fault Codes. Most likely, a car that has been driven for some time will

have a code “Event: ABS Bremsung” stored. This Fault/Event is not

normally shown in the general menu of DAS – it is being filtered. It

actually

does not represent an actual error, just a specific condition (hard

braking with ABS activation). You will find many modules that actually

filter out some more or less useful fault codes.

This menu is also very useful when evaluating vague fault codes (ie:

“Hydraulics fault” in the general version in the developer menu can be

drilled down to something more meaningful like “rear left release valve

stuck in closed state” – this will come in German though).

Adapting the SRS control unit to a new car (different configuration, different VIN).

First of all erase all present error codes in the unit if possible. If

there are current faults the airbag module might not get properly

reinitialized.

Then proceed to the menu control unit adaptations -> special functions -> Control Unit is released.

From this point do not turn the ignition off or reset the control

module. Proceed to the menu option “initial startup” where the current

configuration will be reinitialized and new VIN can be written to the

control unit.

Please pay attention to the specified configuration (ie. Does the car

have rear side airbags?) otherwise you will end up with a controller

that does not recognize airbags installed in the vehicle.

After completing the initial startup, reset the control module (cycle

ignition) and erase all fault codes resulting from the startup process.

Extend SBC life

UNDER NO CIRCUMSTANCES USE THIS PROCEDURE MORE THAN ONCE ON ANY CAR AS

TRUE SERVICE LIFE OF SBC UNIT IS AROUND 160-180% OF WHAT MB SET THE UNIT

AT

Make sure engine is running !!!

In Mercedes Vediamo Developer mode from obd2tool.com you need to go to

Entwickelingsdaten – > ansteueringen -> Gesamstliste aller

Ansteuerungen

to see how many times brake has been pressed there is a line that says: Bremsenzahler (DJ_GetBrLive)

then 1 line down there you see Bremsenzahler aktualisieren und Lebensdauerzahler F neu berechenen -> click it !

Parameter uINBR = 0

then click F3

1 line down Bremsenzahler auf beliebigen Wert setzen (DJ_SetNBr) -> click it

Parameter uINBR = 0

then click F3

then scroll down untill you see the line’s :

Lebensdauerzahler F neu berechenen (DJ_CalcLiveTime)

Parameter uINBR = 0

then click F3

Lebensdauerzahler F neu berechenen und schreiben (DJ_BuildAndWriteF)

Parameter uINBR = 0

then click F3

Log out of SBC !!

log out of verhicle !!

let engine run at least 10 minutes or drive at least 10 minutes

If no coils are damaged , SBC fault code is not AKTUEL no more

Desactivate seat children and ocuppancy seat in mercedes ml270 cdi

MUST READ !!

Warning !! Warning !!

After completing this procedure

NEVER use a child seat in this seat again

Warning !! Warning !!

EXTREME CAUTION TO BE USED WITH THIS METHOD

In obd2tool.com Mercedes Vediamo Developer mode , you have to Disable AKZE in passenger seat.

When you disable this feature, passenger airbag in Dashboard, will work

ALLWAYS when crash signal come’s from the front of the car , even if no

passenger is sitting in this chair . So in an accident from the front,

you allways have to buy a new Dashboard + dash airbag as well

Important !!

After you disabled AKZE in SRS unit ,you will notice you can’t erase the fault , or another fault came back (fault coding).

To complete procedure , you have to unplug the Yellow AKZE connector

under passenger seat, so SRS can’t measure anything connected on this

input port.

Now you can erase Fault codes in SRS , and your SRS light in Instrumentcluster will go off

MUST READ !!

Warning !! Warning !!

After completing this procedure

NEVER use a child seat in this seat again

Warning !! Warning !!

Activate this secret function as litres, datum, bigger pictures/symbols of some check controls on all models

like W211

AGAIN! DISCLAIMER: The author takes no responsibility for any damage

caused by use of the Developer Kit of DAS. This option is a very

powerful tool but must be used responsibly and with extreme caution. If

in doubt, please do not blindly try the menu options – several of them

will cause EEPROM or FLASH memory damage, requiring the module to be

disassembled and reprogrammed using external tools – this is a

troublesome and risky operation. Unintentional actuation of components

may cause mechanical failures or even risk of fire – please remember,

that in obd2tool.com Mercedes Vediamo Developer Mode DAS will do exactly

what you command, all safety checks and interlocks are bypassed!

More question about Mb Star C4 Diagnostic software Xentry DAS Diagnostic Mercedes Vediamo software pls feel free to let me know.

John Deere Service Advisor EDL heavy duty diagnostic adapter

Multi-language available: English, French, Italian, Spanish, Portuguese

Note: HDD comes in English in default. If you need other language, please contact our customer service before ordering.

John Deere Service Advisor EDL (Electronic Data Link) heavy duty diagnostic adapter for construction equipment, agriculture, engines John Deere.

John Deere Diagnostic kit includes software John Deere Service Advisor Agriculture or Construction and Forestry version.

We have two version software V4.0 and V4.2 for john deere service advisor edl v2:

1.V4.0 software: Support Languages: English

2.V4.2 software:Support Languages: English, French, Italian, Spanish, Portuguese

Notice: If you want to do 3038E truck, then need to use V4.2 software (Hardisk Version).

With John Deere Service Advisor PLD File Encryptor/Decryptor you can:

-Decrypt PayLoad (PLD) file to txt/ini format

-Modify PLD file expiration

-Modify PLD factory options such as speed limit (for example change 40 km/h to 50 km/h)

-Adjust PLD file to different product serial

-Encrypt PLD file

-Program controller with modified PLD using Service Advisor

-Support Windows XP

How to change speed limit with pld files?

Q1:

Question about payload files:

I have pld files of my tractor (6330P) 11 in total.

I see in bottom of each files info about my tractor (option, serial number etc)

Question: My goal is up the speed limit from 40km to 50 km. I think I have to change OPTION=3 to OPTION=5, but do I have to edit each 11 pld file?

A1:

You were right about the speed limit:

you can change OPTION=3 to OPTION=4 or any other you need.

Speed_30kmh = 1;

Speed_35kmh = 2;

Speed_40kmh = 3;

Speed_50kmh = 4;

Speed_ECO = 5;

Speed_NoiseRed_OOS = 6;

For R models the line is different. ROADSPEEDLIMIT=3 change to ROADSPEEDLIMIT=5 or any other you need.

var RoadSpeedLimit_30 = “1”;

var RoadSpeedLimit_35 = “2”;

var RoadSpeedLimit_3840 = “3”;

var RoadSpeedLimit_40E = “4”;

var RoadSpeedLimit_50 = “5”;

var RoadSpeedLimit_50E = “6”;

var RoadSpeedLimit_55 = “7”;

var RoadSpeedLimit_60 = “8”;

var RoadSpeedLimit_60E = “9”;

After you change it, sometimes you still need to lift the speed manually through the display (depending on the tractor model)

You only need to reprogram transmission controller for that.

If you reprogrammed all of them, some settings might have went to default so you might get up to 5 fault codes that you need to configure with SA.

Q2:

Does it work with SA 4.2?

A2:

Service Advisor is just a tool to use pld. Pld editor works without SA.

Q3:

I have a question about trying to up the power of a 6330 to a 6430. If I compare the engine pld of both tractor they are identical (just the info in the bottom is different) So I don’t know how it could up the power if all the code is the same??

A3:

most pld files are made for various models, the info at the bottom determines which part of the pld file will be used for programming. For example:

PRODUCT_MODEL_NO=6115

PERFORMANCE_OPTION_PART_NO=R546973

FACTORY_OPTIONS=RE570443

If you want to know model list,please check the link:https://www.cnautotool.com/goods-6996-V52-John-Deere-Service-Advisor-EDL-V2-Electronic-Data-Link-Truck-Diagnostic-Lenovo-T410-Laptop.html

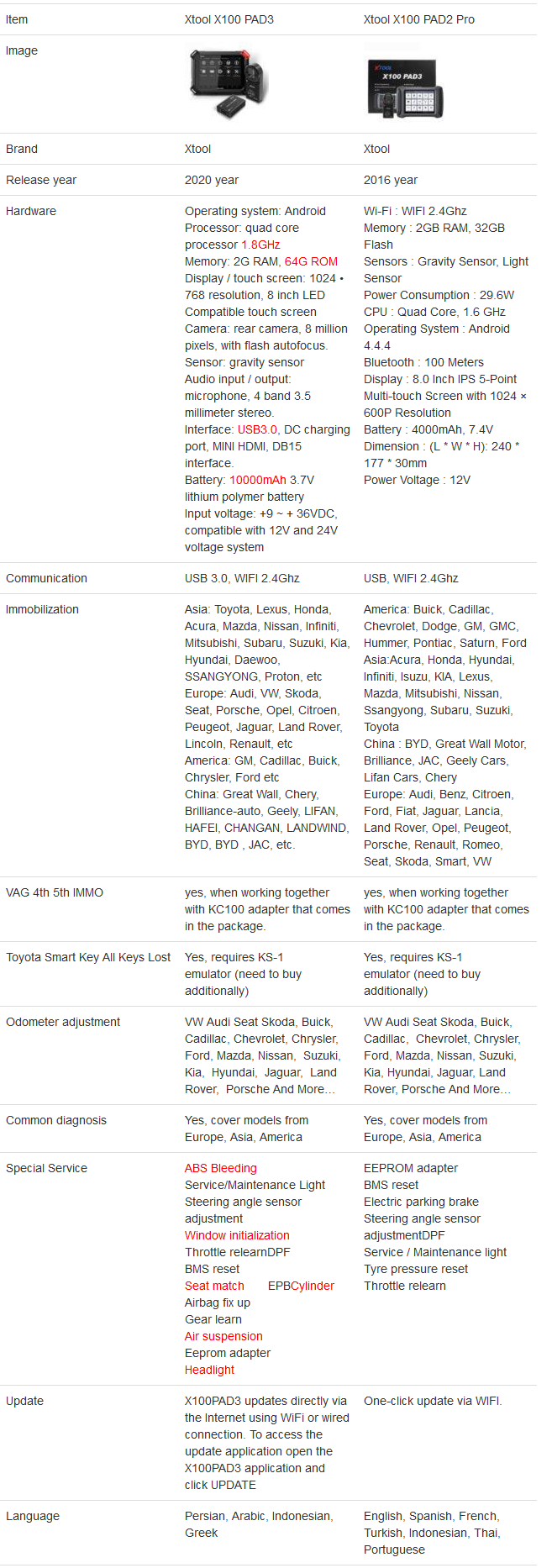

Comparison table of Xtool X100 PAD3 & X100 PAD2 Pro

Xtool X100 PAD3 ( X100 PAD Elite ) is a professional tablet key programmer for all makes, also it supplies advanced special service functions, OBD2 diagnostic functions and mileage adjustment functions. It is the latest Xtool Tablet Key programmer, Upgrade version of X100 Pad/PAD2.

Comparison table of Xtool X100 PAD3 & X100 PAD2 Pro:

Xtool X100 PAD3 tablet key programmer is much better than X100 PAD2 Pro in the aspects of hardware parameters, special functions, car models.

Xtool X100 PAD2 Pro also allows the user to authorize the local car makes, but the software version is 1-year older than that from the local dealer, and the service is free.

Xtool X100 PAD3 Pros:

-All aluminum alloy & silicone: Covered with all aluminum alloy and silicone, X100 PAD Elite has more crash-resistant and durable hardware.

-Android Operating System: The Android-based touch screen tablet features powerful Quad core processor.

– Multi-color UI

X100 PAD3 features simple & elegant appearance design, excellent workmanship and multi-color UI, high-definition display is clearly visible even in direct sunlight.