cnautotool offical blog

the blog of www.cnautotool.comcnautotool offical blog

the blog of www.cnautotool.comNew Holland Diagnostic Software 9.8: A User-Friendly Tool for Vehicle Diagnostics

Are you tired of spending hours trying to diagnose and troubleshoot issues with your heavy vehicles and construction equipment? Look no further than the New Holland Diagnostic Software 9.8. This user-friendly software is designed to make vehicle diagnostics and troubleshooting operations a breeze.

The CNH DPA5 Diagnostic Tool is a universal device that can be used in various industries, including construction, construction sites, and excavation. It is compatible with RP1210 protocols, making it a versatile tool that can be used with a wide range of heavy trucks and construction equipment.

One of the standout features of this diagnostic software is its compatibility with controllers that use a Controller Area Network (CAN) bus. This allows for advanced dataset logging and hidden option programming for vehicles, as well as raw message simulations. With the Electronic Service Tool (EST) Diagnostics Software License, you can easily connect your equipment to the CAN network and perform various diagnostic functions.

Some of the diagnostic functions that can be performed with the New Holland Diagnostic Software 9.8 include controller status/version retrieval, parameter monitoring, fault code retrieval and clearing, electrical and hydraulic schematics, fault code descriptions and repair process, as well as disassembly and reassembly instructions. This comprehensive range of diagnostic functions ensures that you can quickly and accurately identify and resolve any issues with your vehicles and equipment.

In addition to diagnostic functions, the New Holland Electronic Service Tool offers a wide range of features to enhance your diagnostic experience. You can check the status of parameters, retrieve faults, run diagnostic tests, perform ECU and parameter programming, monitor active and logged diagnostics, view and change ECU configuration, access diagnostic procedures and schematics, troubleshoot problems, and even run scope diagnostics. This tool truly provides everything you need to effectively diagnose and maintain your vehicles and equipment.

For those who require additional engine diagnostics and download capabilities, the E.A.S.y tool is available. This tool can be connected directly to the Engine Control Unit (ECU) to perform diagnostic, programming, and ECU reload operations using the K-Line protocol. The CNH Engine Download Tool, which operates within the EST program, provides further engine download operations such as ECU programming update capability, blank ECU initialization and programming capability, ECU programming reassignment, and ECU download crash recovery.

In conclusion, the New Holland Diagnostic Software 9.8 is a must-have tool for anyone in the heavy vehicle and construction equipment industry. Its user-friendly interface, compatibility with a wide range of vehicles and equipment, and comprehensive range of diagnostic functions make it an invaluable asset for vehicle diagnostics and troubleshooting operations. Upgrade to the cnh electronic service tool 9.8 today and experience the ease and efficiency it brings to your diagnostic processes.

New Holland T6030 Power Command Mid-mount Remote Control Valve Assembly

New Holland T6030 Power Command Mid-mount Remote Control Valve Assembly

Are you tired of manually controlling the valves on your agricultural equipment? Look no further because the New Holland T6030 Power Command Mid-mount Remote Control Valve Assembly is here to make your life easier. In this article, we will explore the features and benefits of this incredible piece of equipment.

Features:

The New Holland T6030 Power Command Mid-mount Remote Control Valve Assembly is designed to provide convenience and efficiency in managing the valves of your agricultural machinery. With its user-friendly interface, you can easily operate and control the valves from a comfortable distance, eliminating the need for manual adjustments.

This assembly comes with a mid-mount design, ensuring easy access and visibility of the valves. The strategically placed control panel allows for quick and precise adjustments, making your work more efficient and accurate. The assembly also includes a reliable hydraulic system that ensures smooth and consistent valve operation.

Benefits:

1. Increased Efficiency: With the New Holland T6030 Power Command Mid-mount Remote Control Valve Assembly, you can save time and effort by remotely controlling the valves. This allows for quicker adjustments, reducing downtime and increasing productivity on the field.

2. Improved Safety: Operating valves manually can be challenging and even risky in certain situations. With the remote control feature, you can stay at a safe distance while making adjustments, reducing the chances of accidents or injuries.

3. Versatility: This assembly is compatible with various New Holland agricultural equipment models, making it a versatile addition to your machinery fleet. Whether you have a tractor, harvester, or other equipment, this assembly will seamlessly integrate and enhance their performance.

4. User-Friendly Interface: The control panel is designed with simplicity in mind, ensuring that even operators without extensive technical knowledge can easily understand and operate the assembly. The buttons and indicators are intuitively placed, allowing for effortless adjustments and monitoring.

How to assemble the

New Holland T6030 Power Command Mid-mount Remote Control Valve?

Related Contents:

CNH DPA5 Diagnostic Kit

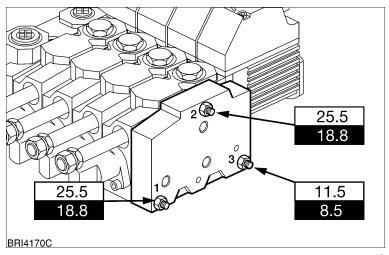

Perform signal valve pressure test for New Holland T6030

New Holland T6030 Tractor Primary Hydraulic Remote Valve Disassemble Guide

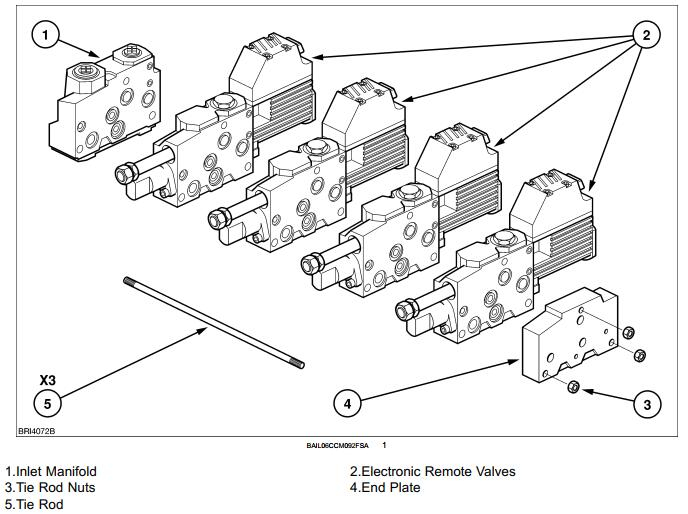

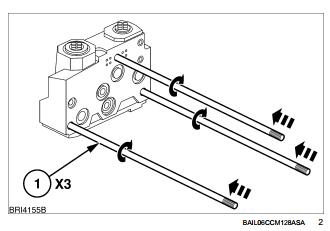

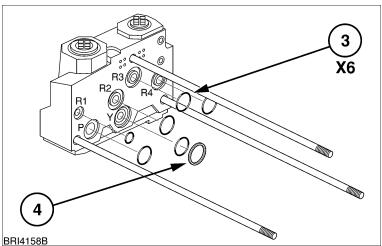

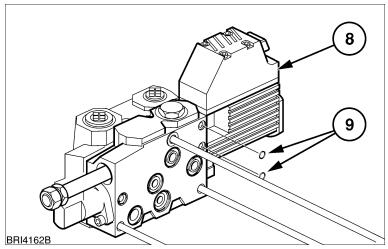

1. Start by inserting the tie rods into the inlet manifold and screw them in by hand as far as they will go.

2. If any adhesive shims have been used previously, push a shim onto the tie rods.

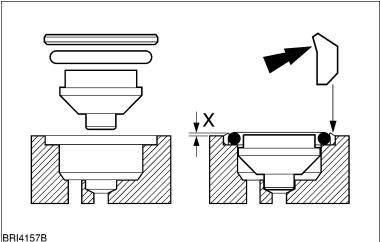

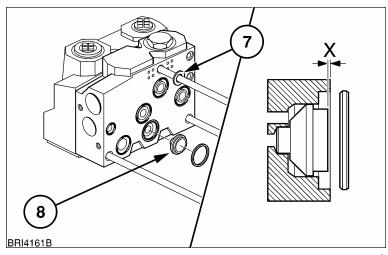

3. Insert the load sensing shuttle valve along with the ‘O’ ring and

support ring into port ‘Y’, as shown in Figure 4. Make sure that

clearance X is approximately 0.5 mm from the flange face of the valve

segment to the top edge of the inserted shuttle valve.

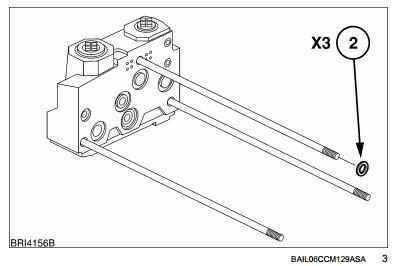

4. Insert new ‘O’ rings into the pressure and return ports, as well as the load sense ‘O’ ring and support ring.

5. Insert new ‘O’ rings into the pilot line oil holes.

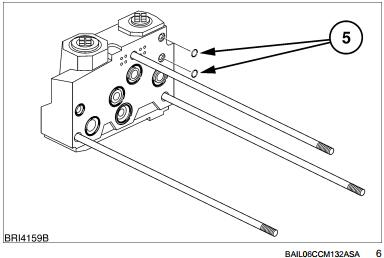

6. Place the first valve slice onto the tie rods and insert new ‘O’ rings into the relevant ports.

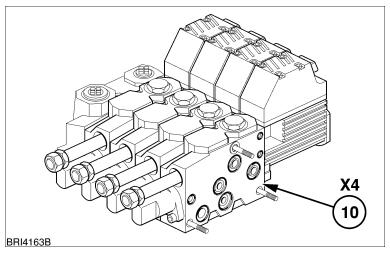

7. If the flange face has corrugations that have been smoothed with a

dressing stone, thread one spacer onto each tie rod. Insert the load

sense valve and support ring as shown. Again, ensure that clearance X is

approximately 0.5 mm from the flange face of the valve segment to the

top edge of the inserted shuttle valve.

8. Insert the ‘O’ rings into the control oil holes.

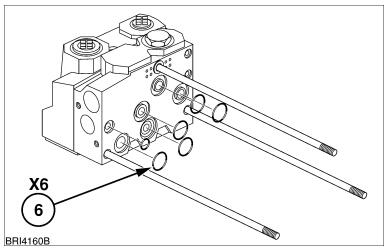

9. Push the last slice onto the tie rods and insert the ‘O’ ring.

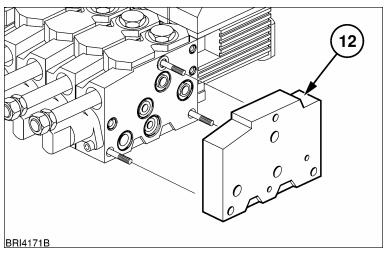

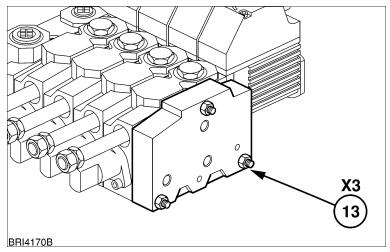

10. Fit the end plate.

11. Push the end plate onto the tie rods and screw on the nuts by hand.

12. Place the now assembled valve stack onto a level surface to correctly align the sections.

Investing in the New Holland T6030 Power Command Mid-mount Remote Control Valve Assembly is a wise decision for any agricultural professional. Its features, including the mid-mount design, user-friendly interface, and compatibility with various equipment models, make it an essential tool for efficient and safe valve control. Upgrade your agricultural machinery today and experience the convenience and benefits this assembly has to offer.