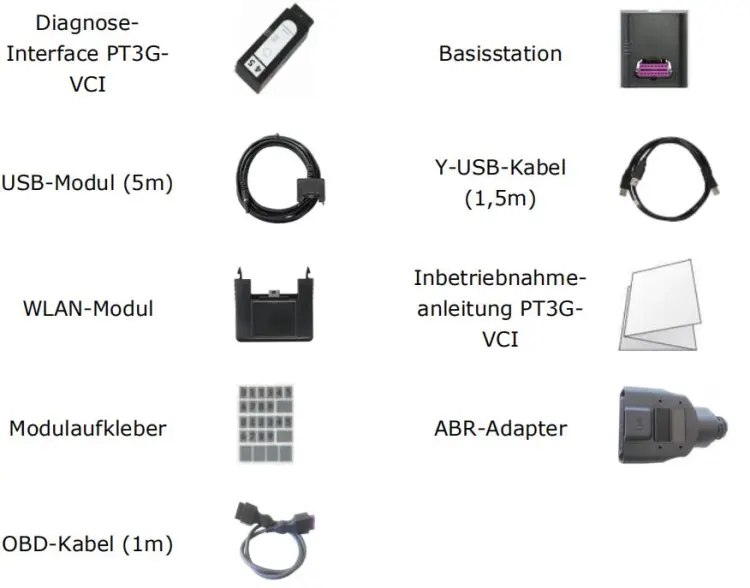

What does the Porsche VCI diagnostic interface include?

2.TECHNICAL DATA OF THE DIAGNOSTIC INTERFACE PT3G-VCI

Module interface: mini USB socket

Power consumption: approx. 5W in operation

Storage temperature: -20 ° C… + 85 ° C

Operating temperature: -20 ° C… + 40 ° C

Power supply: 8 … 18V via diagnostic interface (OBD)

Power consumption

with WLAN module

via diagnostic interface

Normal operation: 300mA / 13.8V,

Shutdown stage 1: 250mA / 13.8V

Shutdown stage 2: 5mA / 13.8V

RAM: 256MB DDR RAM

Permanent memory: 16MB NOR, 4 GB NAND flash

Dimensions: 110 x 48 x 25 mm (LxWxH)

Weight: 90 g

Vehicle interfaces:

High speed CAN

according to ISO 11898-2 o CAN 2.0B with 11- and 29-bit identifier

maximum data rate 1Mbit / s

Low speed CAN

maximum data rate 125kbit / s

-according to ISO 11898-2 Vehicle Ethernet

according to ISO 13400

maximum 100Mbit / s

Ethernet activation switchable

K line

for 12V vehicle systems

according to ISO 9141-2 (max.sink current 300mA)

maximum data rate 125kbit / s

510 ohm line pull-up (can be deactivated)

KL30 voltage measurement

KL15 voltage measurement

Voltage measurement at pin 8 and 9 of the diagnostic connector

3.WLAN MODULE

With the WLAN module, the PT3G-VCI is able to establish a direct

connection via the WLAN interface to the diagnostic device or to the

corresponding infrastructure of the workshop network. For this The WLAN

module supports the modes infrastructure and direct connection (WLAN

access point).

TECHNICAL DATA OF THE WLAN MODULE

Network interface: WLAN 802.11 a / b / g / n 2T2R 300Mbit / s, 2.4 GHz and 5 GHz

Client mode (WPA2-PSK, WPA2-EAP / TLS)

AP mode (WPA2-PSK)

VAS interface: mini USB plug

Storage temperature: -20 ° C… + 85 ° C

Operating temperature: -20 ° C… + 40 ° C

Dimensions: approx. 46 x 48 x 25 mm (WxDxH)

Weight: 22 g

DIAGNOSTIC DEVICE SYSTEM REQUIREMENTS

For the diagnostic device with which the PT3G-VCI is to be configured via the base station

the following system requirements are met:

Operating system: Windows 7, 8.1 (32 & 64 bit)

PIWIS Tester III

Interfaces: 2 x USB 2.0 (or higher, see PIWIS Tester III)

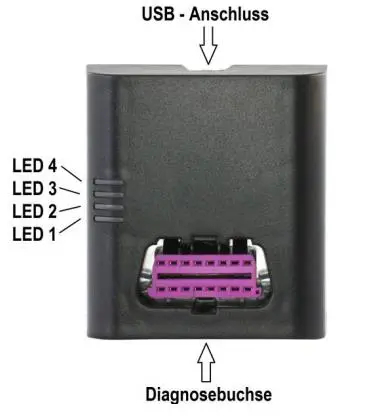

4.BASE STATION

The base station is used to configure and self-test the PT3G-VCI. It is

connected to the diagnostic device using the included Y USB cable.

The base station has 4 green LEDs on the top.

TECHNICAL DATA OF THE BASE STATION

Diagnostic device interfaces: USB 2.0 high speed, 480Mbit / s

(Need two USB interface data cables to provide power)

VCI interface: diagnostic socket

Power consumption: Without PT3G-VCI: 0.25W

with PT3G-VCI: 5W

Storage temperature: -20 ° C… + 85 ° C

Operating temperature: -20 ° C… + 40 ° C

Dimensions: 80 x 90 x 36 mm (WxDxH)

Weight: 146 g

more information at: https://www.cnautotool.com/goods-6976-Porsche-Tester-III-Diagnostic-Tool-Piwis-3-Software-Installed-Laptop.html